As the semiconductor industry advances, the environmental footprint of manufacturing has become a growing concern. The transition to 3D semiconductor packaging, while enabling significant performance gains, also presents sustainability challenges. Erik Hosler, a prominent voice in semiconductor innovation, highlights the urgency of addressing these issues, noting that sustainable practices are essential to achieving carbon neutrality goals while meeting the demands of modern technology.

The Environmental Challenges of 3D Packaging

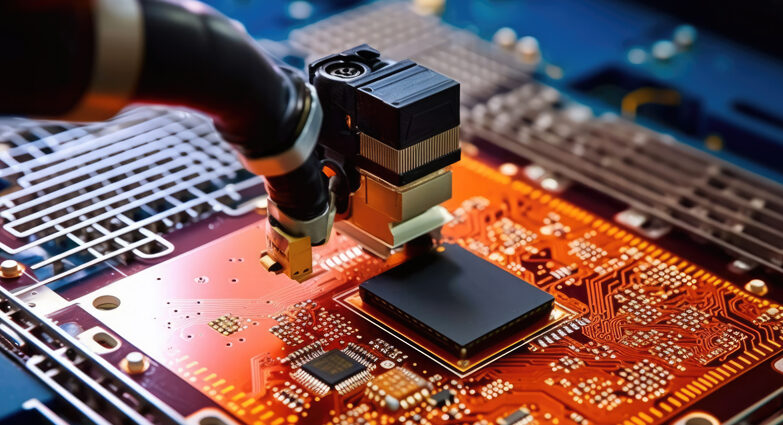

Unlike traditional 2D designs, 3D semiconductor packaging involves stacking multiple layers of circuits, increasing the complexity of manufacturing processes. These advanced designs often require high energy consumption, substantial water usage and significant material resources. For instance, the production of cutting-edge chips for AI and cloud computing applications can strain energy grids and water supplies, particularly in regions with limited resources.

Sustainable Practices in 3D Semiconductor Packaging

To address these environmental challenges, the semiconductor industry is embracing innovative sustainable practices that significantly reduce its ecological footprint. One critical approach is material reuse and recycling, where valuable resources like silicon wafers and rare earth metals are reclaimed and repurposed. This method not only conserves finite resources but also reduces the need for new extractions, thereby minimizing waste and lowering the overall carbon footprint of manufacturing.

Energy-efficient manufacturing is another key focus, with advanced production techniques—such as energy-efficient lithography—being integrated into fabrication processes. Factories are increasingly adopting renewable energy sources to power their operations, aligning with global sustainability goals while reducing electricity consumption.

Equally important is water conservation, achieved through the implementation of closed-loop water recycling systems. These systems capture, purify and reuse water within the manufacturing cycle, significantly reducing freshwater consumption and waste. Together, these sustainable practices are helping the semiconductor industry balance technological innovation with environmental responsibility.

Driving Sustainability Goals Through Innovation

Sustainability in semiconductor manufacturing relies heavily on innovation to balance environmental responsibility with technological advancement. Erik Hosler points out, “Light source development and lithography advancements are shaping the future of semiconductor applications, where light will drive the next wave of innovation.” By incorporating cutting-edge technologies like high-efficiency lithography and advanced cooling solutions, manufacturers are making strides toward sustainable 3D packaging.

Sustainability in 3D semiconductor packaging is not just a responsibility—it is a necessity to align with global carbon neutrality goals. By integrating practices like material reuse, energy-efficient manufacturing and water conservation, the semiconductor industry is setting a new standard for innovation with minimal environmental impact. As these efforts continue, the future of 3D packaging will be defined by a balance of performance, scalability and sustainability, ensuring that technological advancements do not come at the expense of the planet.